HEAT TREAT

Annealing – Our annealing process allows for a range of available Stress Relieved and Annealed tempers. These are achieved through the use of specific temperatures to achieve desired material and metallurgical properties. Annealing of certain brass alloys can also aid in corrosion resistance such as dezincification and stress corrosion cracking. Our annealing process softens brass by changing its molecular structure through the use of heat treatment. Annealing brass can prolong brass life and increase its consistency.

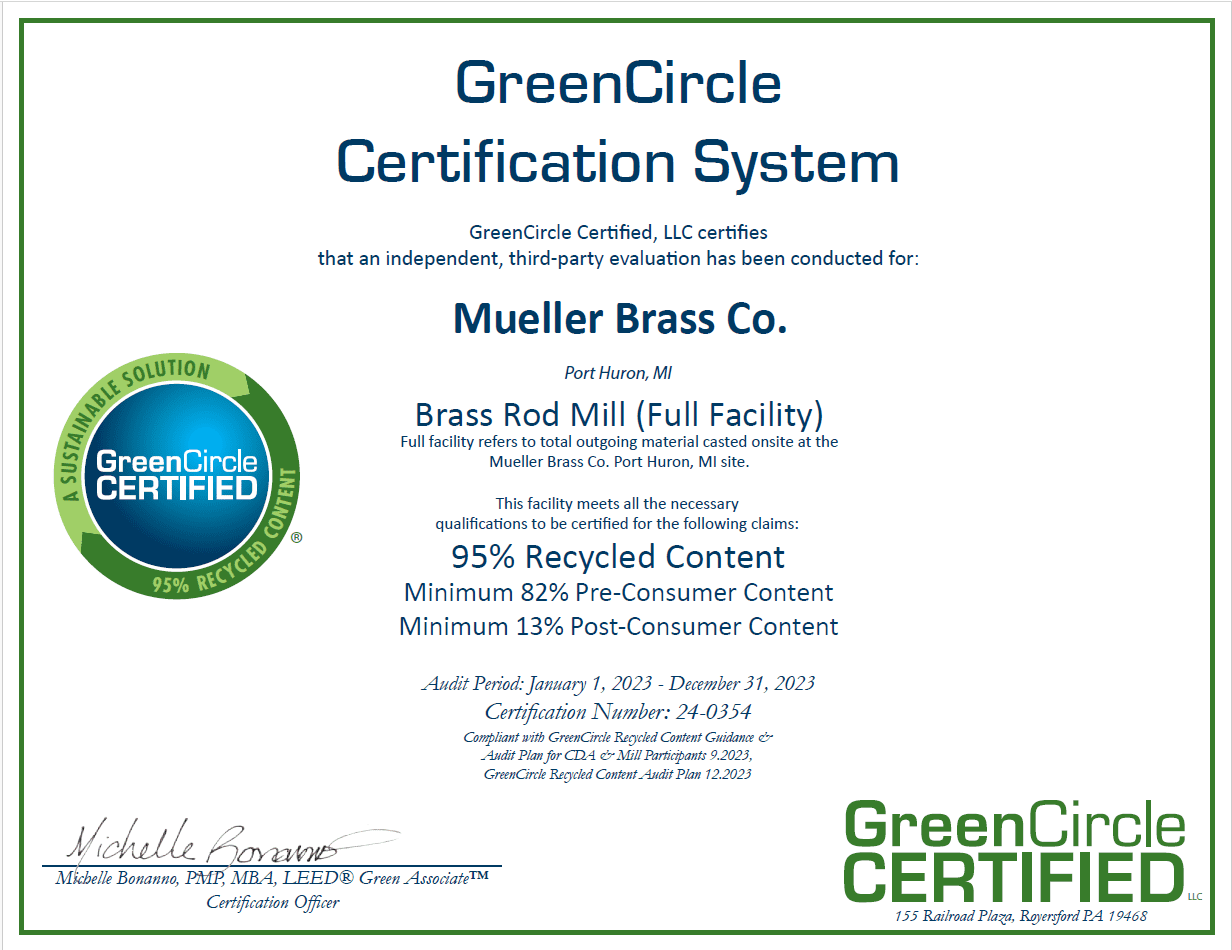

Recycling

To begin, Mueller Brass Co recycles all brass that does not leave our mill as verified, within-specification product.

Recycling – Mueller Brass Co. has set the industry standard in the brass rod industry in the United States for Average Recycled Content found in brass rod: 82% Pre-Consumer, 13% Post-Consumer with an overall 95% Recycled content. Brass is the ultimate example of recyclability as it can be endlessly reused and recycled with no loss to physical, chemical, or mechanical characteristics. Mueller Brass Co. encourages the recycling of brass to its customers for sustainability and economical purposes.

Scrap Intake – Mueller Brass Co. receives scrap from various sources and in many forms. First, the brass rod mill recycles all brass that does not leave our facility as verified, within-specification product. Next, Mueller Brass Co. has implemented a scrap buyback program that allows customers to send back their brass scrap to our mill for recycling. Finally, Mueller Brass Co. purchases from reputable external brass scrap suppliers to supplement their deficit in required material to create more brass rod inventory. Our scrap intake and stream are vital to our manufacturing process.

How is it tested? Our scrap intake is tested by our M.E.T Lab to ensure accurate chemical composition determination before entering our scrap stream. This ensures that our scrap stream is not at risk of cross-contamination from unwanted elements.