QUALITY CONTROL

Mueller Brass Co. takes immense pride in the quality of our products. With over a century of experience, Mueller Brass Co. has extensive knowledge of quality concerns and how to adjust our processes to ensure a quality product every time.

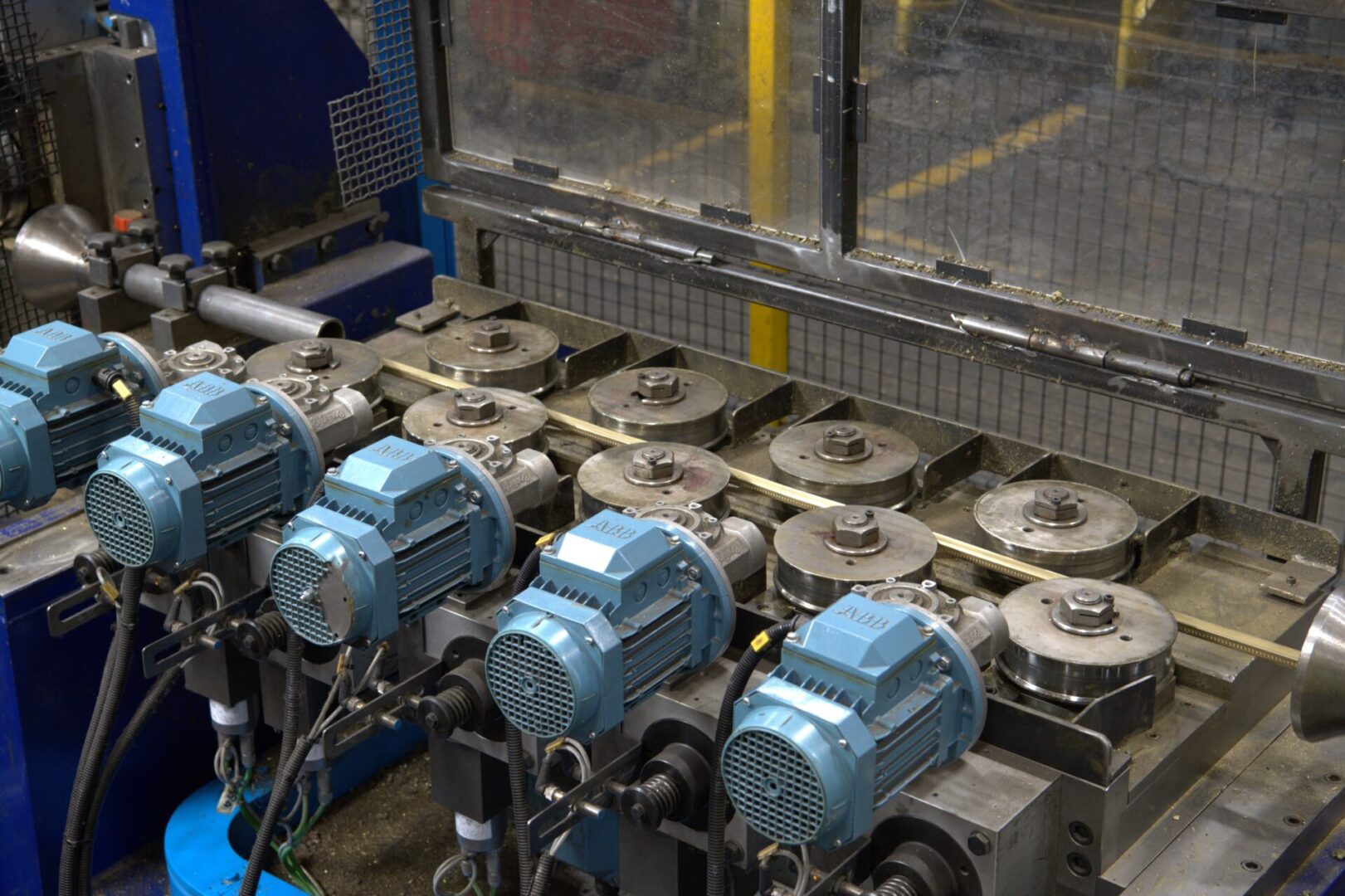

Non-Destructive Testing (NDT) – The introduction of the following systems, processes and checks are part of the major investment in our finishing segment to improve product quality and gather data for systemic upstream improvements in our manufacturing process.

- Eddy Current (EC) – This technology checks for surface finish impurities in our brass rod before it is shipped out to the customer. Mueller Brass Co. maintains consistent material quality by detecting surface defects on the bar.

- Laser Measurement Equipment – Our Laser Measurement Equipment technology uses 3-axis and 2-axis lasers to detect dimensional tolerances and corners. This ensures our product is made to customer specifications and is within product specifications.

- Straightness Detection – Mueller Brass Co. has invested in lasers to detect variances in straightness, which is done well before bundling to ensure our customers receive straight material.

- Handheld XRF Analyzer – Mueller Brass Co. has invested in multiple XRF Analyzers which allows our quality team to inspect and verify alloy compositions on the shop floor. This gives them accurate readings as to what is being shipped and the opportunity to verify orders before shipment, ensuring our customers receive the correct alloy.

- 24/7 Quality Engineer Team – A 24/7 quality engineer team monitors, inspects, and verifies our brass rod. This team works closely with Customer Service to address and correct any customer concerns. Our team of experienced Quality Engineers ensure that quality material is being shipped to our customers.