CASTING

Raw material begins its transformation into rod and bars via the casting process. Casting is the process by which raw material is melted and cast into ‘logs’ which are then cut into billets. Mueller Brass Co. incorporates two forms of casting: Horizontal Continuous and Vertical Semi-Continuous.

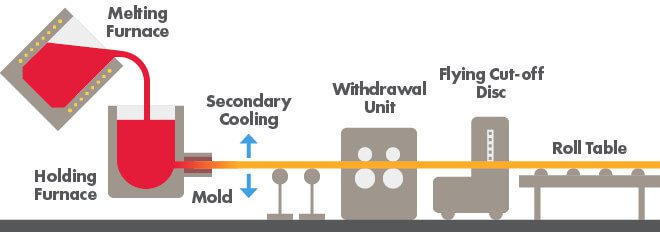

Horizontal Continuous Caster

Mueller Brass Co. dedicates its horizontal continuous caster to our most popular alloys such as C36000, C37700, etc. This component of our manufacturing process allows us to optimize our throughput and maintain a healthy inventory of high demand brass alloys.

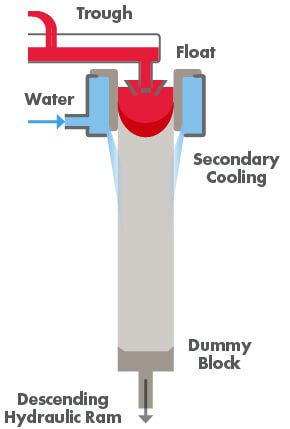

Vertical Semi-Continuous Caster

Our semi-continuous caster is used for specialized alloys requiring a more batch-like process. This added feature provides manufacturing flexibility by casting smaller volumes of more specialized alloys.